OEM Rubber Coated Cable Clamps Suppliers – Wire Laying Construction Steel Cable Socks Mesh Sleeve Cable Net Sleeve Conductor Mesh Socks Joint – Donghuan Power

OEM Rubber Coated Cable Clamps Suppliers – Wire Laying Construction Steel Cable Socks Mesh Sleeve Cable Net Sleeve Conductor Mesh Socks Joint – Donghuan Power Detail:

Product introduction

The high-strength traction rope used for electric paying off traction has high breaking strength, light weight, water resistance, UV resistance, corrosion resistance, acid and alkali resistance, and is covered with a wear-resistant sheath. The product is soft and has a long flexural life. And the product has good insulation.

The material of high-strength traction rope is generally divided into Dinima fiber, DuPont silk and nylon according to the requirements of traction strength.

The inner core is made of 12 strands of twisted fiber, with high strength. The outer sheath is made of 24 strands of tightly woven, with good wear resistance.

The high tensile strength of high-strength traction rope can effectively improve the load. Its low elongation can effectively control the sag, making the sag drop as small as possible under load.

The good insulation and moisture-proof performance of high-strength traction rope can ensure the safety of personnel and equipment during live crossing construction.

The material of high-strength traction rope is light. Under the condition of the same breaking tensile strength, the weight per meter of high-strength traction rope is only 15% of that of steel wire rope. The use of high-strength traction rope is conducive to reducing labor intensity and improving work efficiency.

The high-strength traction rope has good bending fatigue resistance, wear resistance, weather resistance, UV protection, chemical corrosion resistance and other characteristics, which is conducive to recycling in the crossing construction.

High strength braided nylon rope TECHNICAL PARAMETERS

Nylon material

|

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

|

6 |

8.6 |

20±0.3 |

16 |

41.6 |

153±1.5 |

|

8 |

12.8 |

44±0.5 |

18 |

51.2 |

193±2 |

|

10 |

17.6 |

63±1 |

20 |

60.8 |

222±3 |

|

12 |

24 |

93±1 |

22 |

70.4 |

268±3 |

|

14 |

32.3 |

117±1.5 |

24 |

80 |

318±4 |

DuPont silk material

|

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

|

6 |

10 |

35±0.3 |

14 |

60 |

148±1.5 |

|

8 |

16 |

60±0.5 |

16 |

80 |

180±1.5 |

|

10 |

30 |

80±1 |

18 |

100 |

230±2 |

|

12 |

50 |

114±1 |

20 |

120 |

290±3 |

Dinima material

|

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

Diameter(MM) |

Break force(>KN) |

Linear density(G/M) |

|

6 |

19 |

16±0.3 |

14 |

137 |

113±1.5 |

|

8 |

31.9 |

28±0.5 |

16 |

180 |

150±1.5 |

|

10 |

58.8 |

48±1 |

18 |

211 |

177±2 |

|

12 |

92.5 |

77±1 |

21 |

296 |

247±3 |

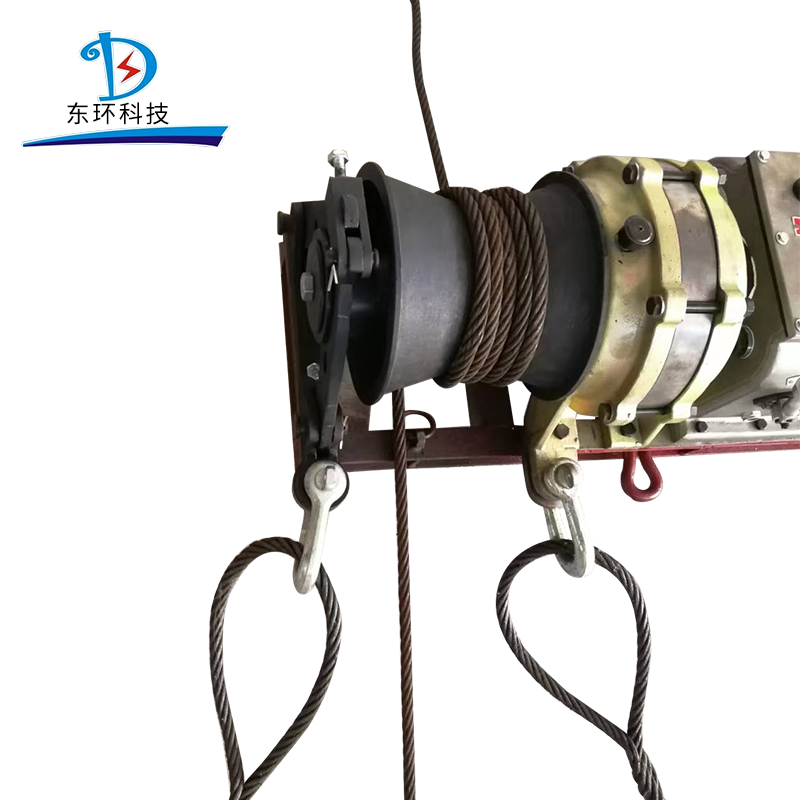

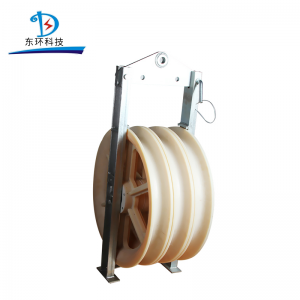

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for OEM Rubber Coated Cable Clamps Suppliers – Wire Laying Construction Steel Cable Socks Mesh Sleeve Cable Net Sleeve Conductor Mesh Socks Joint – Donghuan Power , The product will supply to all over the world, such as: panama, Ecuador, moldova, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.