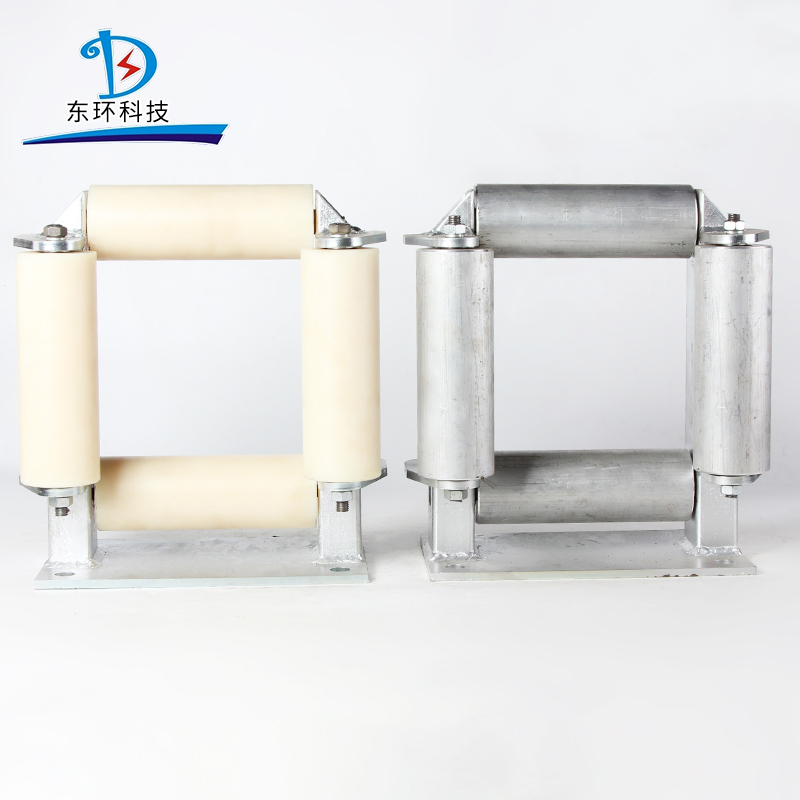

Cable Roller Nylon Aluminum Steel Sheave Ground Cable Pulling Pulley

Product introduction

Cable rollers should always be used when pulling cables. Straight cable runs are pulled in using straight cable rollers suitably placed in the ground, avoid damaging cable surface sheath by friction between cable and ground. Straight cable runs are pulled in using straight cable rollers suitably placed in the cable trench to prevent the cable being dragged on the trench bottom or in mud. Cable roller spacing is dependent on cable type being laid and the cable pulling tension along the route. Leading cable rollers are used to support the cable over the entire drum width immediately before being pulled into the trench.

According to the ground environment and usage habits, the cable roller has three structures. Respectively: casting aluminum structure, steel plate structure and steel pipe structure. Steel pipe structures are also divided into simple and reinforced structures

Common cable pulley specifications include outer diameter 120mm* wheel width 130mm, outer diameter 140mm* wheel width 160mm, outer diameter 120mm* wheel width 200mm and outer diameter 140mm* wheel width 210mm, etc.

Nylon sheaves are represented by N letters.The rest are aluminum sheaves. The steel wheel needs to be customized.

Ground Cable Roller Technical Parameters

|

Item number |

Model |

Applicable Cabe(MM) |

Rated load (kN) |

Carrier Structure |

Weight (kg) |

|

21171 |

SHL1 |

≤ Φ150 |

5 |

Casting Aluminum |

5.4 |

|

21172 |

SHL1N |

5 |

3.6 |

||

|

21181 |

SHL1B |

≤ Φ150 |

5 |

Steel Plate |

5.5 |

|

21182 |

SHL1BN |

5 |

3.7 |

||

|

21183 |

SHL2BN |

≤ Φ160 |

5 |

5.5 |

|

|

21184 |

SHL3BN |

≤ Φ200 |

5 |

8.0 |

|

|

21191 |

SHL1G |

≤ Φ150 |

5 |

Steel Pipe |

5.1 |

|

21192 |

SHL1GN |

5 |

3.3 |

||

|

21193 |

SHL2GN |

≤ Φ160 |

5 |

6.5 |

|

|

21194 |

SHL3GN |

≤ Φ200 |

5 |

8.5 |