Triple Wheels Neoprene Lined Aluminum Sheaves Coated Rubber Stringing Block

Product introduction

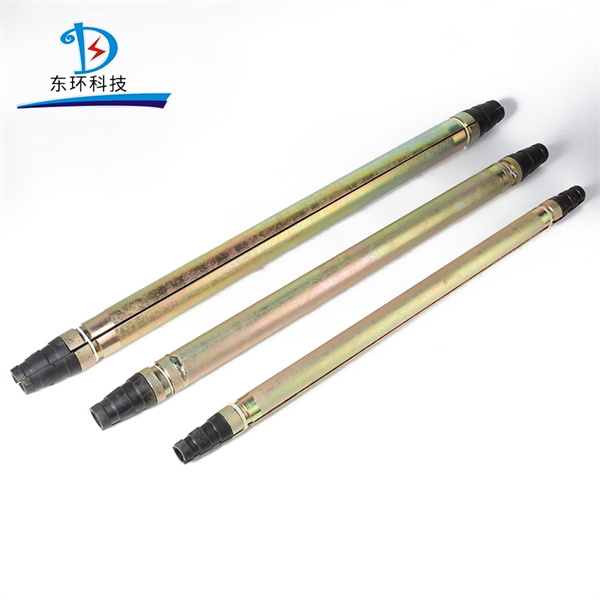

Aluminum Sheaves Coated Rubber Stringing Block, the aluminum sheave or the nylon sheave used as the base material, and the sheave groove is coated with rubber. Before coating, the groove surface of the aluminum sheave or the nylon sheave needs to be specially processed, Then the high temperature rubber pressing process is adopted, so that the rubber layer can be firmly adhered to the aluminum sheave or the nylon sheave.

The purpose of aluminum sheave or the nylon sheave coating with rubber is that when the conductor is pulled through the sheave groove, the surface of the conductor and the pulley groove will generate friction, and the outer surface of the conductor will be damaged to a certain extent. The rubber coating on the aluminum sheave or the nylon sheave can reduce the damage caused by this friction.

Stringing block can be divided into single sheave, three sheaves and five sheaves according to the number of sheaves. According to sheave diameter, it can be divided into (outside diameter × sheave width) of Φ308×75, Φ408×80 and Φ508×75 (mm), etc. Sheave size can be customized according to needs. The number of sheaves can also be customized.

Product description

1. Rubber coated stinging block for conductor transmission line passing

2. Any sizes of stringing block(outside diameter*root diameter*sheave width) accept to customize

3.OEM and ODM service

4.Nylon sheaves or aluminum sheaves is coated with rubber (neoprene)

Aluminum Sheaves Coated Rubber Stringing Block Technical Parameters

|

Item Number |

Model |

Sheaves |

Sizes |

Rated Load |

Weight |

|

10241JS |

SHSLJ308 |

3 |

308×75mm |

35KN |

28KG |

|

10199JS |

SHSLJ408 |

3 |

408×80mm |

40KN |

35KG |

|

10102JS |

SHSLJ508 |

3 |

508×75mm |

40KN |

45KG |